Overview of Electric Cost of Service Studies

For a pdf version of this article, please click here

There are a number of considerations in determing the level and structure of the rates that a utility should charge its customers. The starting point in assessing the reasonableness of the rates to be charged by a utility is to evaluate the cost of providing service. Utilities perform cost of service studies to determine what it costs to provide service to its customers, both in total and by individual rate class (e.g. residential, commercial, industrial).

A cost of service study is one of the most effective analytic tools that a utility can rely on for designing rates that equitably assign cost responsibility to each customer rate class, to the mutual benefit of both the utility and its customers. It is important, then, for the utility to prepare a cost of service study using standard methodologies that have been established by industry experts, accepted by regulatory commissions, and approved by the courts. These methods must determine as accurately as possible what it costs for the utility to serve a class of customers.

The overall cost of service study approach outlined herein is consistent with principles established by the National Association of Regulatory Utility Commissioners ("NARUC") and with the NARUC Cost Allocation Manual. The approach has been accepted by public utility regulators in the U.S. and Canada and is supported by an extensive body of utility case law.

Principal Steps of a Cost of Service Study

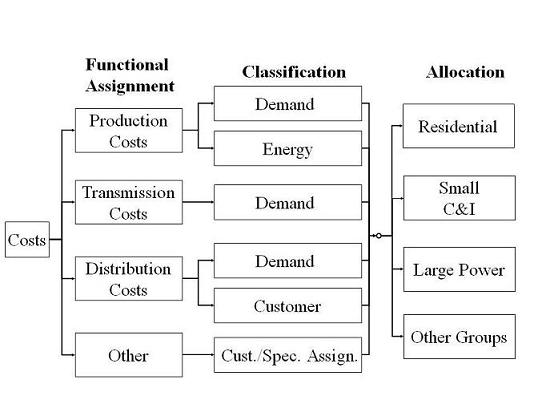

The three principal steps of an embedded cost of service study are Functional Assignment, Classification, and Allocation. These three steps are necessary to ensure that the costs allocated to a class of customers reflect as accurately as possible the costs that the particular customer class causes the utility to incur. The overall approach for performing a cost of service study is depicted in Figure 1.

1. Functional Assignment

In the first step, costs are assigned (or “functionalized”) to the major functional groups related to providing service. Functional assignment involves assigning costs to the functional services provided by a utility, such as power production, purchasing electric power, the transmission of the power over high-voltage lines (typically at voltages of 69 KV or higher), and the distribution of power over distribution lines (typically at voltages of less than 69 KV). Functional assignment serves the following purposes: (1) it groups associated costs together to facilitate allocation on the basis of cost responsibility; (2) it provides a rational mechanism for grouping costs that do not appear to be related to major service functions; and (3) it provides a device for separating assignable costs from joint costs, which must be allocated. Functionally assigning all costs permits the utility to examine its revenue requirement in finer detail and to more accurately assign cost responsibility in the next two steps of the study.

In many cost of service studies, the following functional groups are used in order to provide a high degree of detail for purposes of designing rates as well as analyzing and tracking costs:

- • Production

- • Purchased Power

- • Transmission

- • Station Equipment

- • Primary & Secondary Distribution Plant

- • Customer Services

- • Distribution Meters

- • Lighting Systems

- • Meter Reading, Billing & Customer Service

- • Load Management

2. Classification

In the second step, the major cost drivers are identified (or "classified") for each group of functionally assigned costs. Identifying the major cost drivers allows the service characteristics that give rise to the costs to serve as a basis for allocation. Once the costs are functionally assigned they are then ordinarily classified by the following major cost drivers:

- • Energy-related costs

- • Demand-related costs

- • Customer-related costs

FERC Predominance Methodology

Many utilities classify production operation and maintenance ("O&M") expenses as fixed and variable using an approach recognized by the Federal Energy Regulatory Commission ("FERC") known as the predominance methodology. Under the FERC predominance methodology, production O&M accounts that are predominately fixed (i.e. expenses that the FERC has determined to be predominately incurred independently of consumption) are classified as demand-related. Production O&M accounts that are predominately variable (i.e., expenses that the FERC has determined to vary predominately with usage) are considered to be energy related. The predominance methodology has been accepted in FERC proceedings for decades and is a standard methodology for classifying production O&M expenses.

Minimum System vs. Zero Intercept

There are two commonly used methodologies for determining demand/customer splits of distribution plant, namely the “minimum system” methodology and the “zero-intercept” methodology.

In the minimum system approach, a “minimum” standard conductor size is selected and the minimum system is obtained by pricing all of the distribution conductors at the unit cost of this minimum size. The minimum system determined in this manner is then classified as customer-related and allocated on the basis of the number of customers in each rate class. All costs in excess of the minimum system are classified as demand-related. The theory supporting this approach maintains that in order for a utility to serve even the smallest customer, it would have to install a minimum size system. Therefore, the costs associated with the minimum system are related to the number of customers that are served, instead of the demand imposed by the customers on the system.

The theory behind the zero-intercept methodology is that there is a linear relationship between the unit cost ($/ft) of conductor and its current-carrying capability, which is proportionate to its diameter. After establishing a linear relation, which is given by the equation:

y = a + bx

where

y is the unit cost of the conductor,

x is the size of the conductor, and

a, b are the coefficients representing the intercept and slope, respectively

it can be determined that, theoretically, the unit cost of a conductor with zero diameter (or wire with zero load carrying capability) is a, the zero intercept. The zero intercept is essentially the cost component of lines that is invariant to the size (and load carrying capability) of the wire.

In most electric distribution systems, the number of feet of conductor is not uniformly distributed over all sizes of wire. For this reason, it is necessary to use a weighted regression analysis, instead of a standard least-squares analysis, in the determination of the zero intercept. Using a weighted regression analysis, the cost and diameter of each size conductor is, in effect, weighted by the number of feet of installed conductor. In a weighted regression analysis, the following weighted sum of squared differences

is minimized, where w is the weighting factor (in this case the feet of wire) for each size of wire, and y is the observed value and y is the predicted value of the dependent variable (in this case the unit cost of the wire).

The zero-intercept methodology is less subjective than the minimum system approach and is strongly preferred over the minimum system methodology when the necessary data is available. With the zero-intercept methodology, the utility is not forced to choose a minimum size conductor to determine the customer component. In the zero-intercept methodology, a zero-diameter conductor is the absolute minimum system. Both methods have been accepted by utility regulators across the country.

3. Allocation

In the third and final step, the functionally assigned and classified costs are directly assigned (or "allocated") to the customer classes on the basis of an allocation factor that is representative of the service characteristic that drives the utility’s costs. For example, energy-related costs are allocated on the basis of the amount of kilowatt hours used by the customer class and demand-related costs are allocated on the basis of the appropriate measurement of the maximum demand that the customer class places on the system.

The reason that allocation procedures must be used to determine the cost of providing service to each rate class is that most of a utility’s costs are represented by what are referred to as joint costs. Joint costs are those costs incurred jointly for two or more types of operations where each operation does not have a separate incremental cost function. In the electric utility industry, production, transmission and most distribution facilities are jointly engaged in providing service to a multitude of customers. These customers have diverse load characteristics, taking service at different rates with a variety of usage patterns at various times of the day, month or year. Consequently, in the utility industry very few costs can be directly attributed to specific customers or specific customer groups. Those that are may be directly assigned to a particular customer or customer class (e.g. a substation or other facility that provides service exclusively to a large industrial plant, military base, or special contract customer). However, most of the utility’s costs must be allocated to the customer classes on the basis of an allocation process that reasonably attributes costs on the basis of cost causation.

Variations

All utilities are not required to perform cost of service studies exactly the same way. However, variations usually relate to specificity of data, not to the overall approach. When the cost data is available in a more granular fashion, the study provides greater certainty around the information for each rate class. Studies are most easily undertaken when the utility adheres to an established, well-accepted accounting standard like the FERC Uniform System of Accounts or the Rural Utilities Service ("RUS") Uniform System of Accounts outlined in RUS Bulletin 1767B-1.

Conclusion

Cost of service studies that are properly developed -- by following the essential three steps of functional assignment, classification and allocation -- will permit the utility to more fully understand the impact of its costs and to design rates that properly assign cost responsibility to each customer rate class. This ultimately provides significant and mutual benefits to both the utility and its customers.

Larry Feltner is a Senior Consultant at The Prime Group, LLC, a consulting firm specializing in rate and regulatory matters for utilities. Contact the author at 502.241.4684 or at lfeltner@theprimegroupllc.com.